technical masterpiece

Cleanroomcranes

from ALTMANN

ALTMANN is a world leader in the development and production of cleanroom cranes. Our team has designed, manufactured and assembled the biggest cleanroom cranes worldwide to date: two double girder overhead cranes with 2 synchronized hoists at 15 tons of lifting capacity each and a span of 30 m each.

technical masterpiece

Cleanroom cranes from ALTMANN

ALTMANN is a world leader in the development and production of cleanroom cranes. Our team has designed, manufactured and assembled the biggest cleanroom cranes worldwide to date: two double girder overhead cranes with 2 synchronized hoists at 15 tons of lifting capacity each and a span of 30 m each.

The ALTMANN

Cleanroom cranes

the Cleanroom cranes from various industries

semiconductor industry

semiconductor industry

Cleanroom single girder overhead crane

Cleanroom single girder overhead crane

Purpose

precise placement of costly assemblies

Functions

- Lifting capacity: 4 tons

- Span: 8,185 mm

- Lifting height: 5,500 mm

- Cleanroom class: ISO 6

- with anti sway control

- with positioning accurate to the millimeter

- with semiautomatic

semiconductor industry

semiconductor industry

Cleanroom double girder overhead crane

Cleanroom double girder overhead crane

Purpose

extremely sensitive mounting and handling of high-precision machine assemblies

Functions

- Lifting capacity: 2 x 8 tons each crane

- Span: 10,250 mm

- Lifting height: 10,500 mm

- Cleanroom class: ISO 5/6

- Synchronisation accuracy: +/- 1 mm for each axis

- 2 synchronous long travel axes

- 4 synchronous cross travel axes

- 4 synchronous hoist axes

semiconductor industry

semiconductor industry

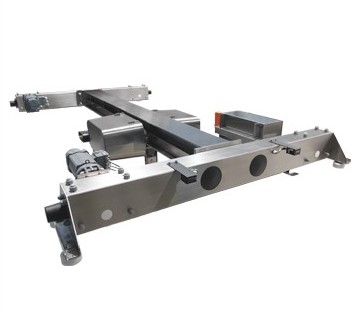

Cleanroom double girder overhead crane

Cleanroom double girder overhead crane

Purpose

sensitive mounting and dismounting of machine assemblies and extremely sensitive handling of products

Functions

- Lifting capacity: 5 tons each crane

- Span: 9,180 mm

- Lifting height: 4,010 mm

- Cleanroom class: ISO 6

- Synchronisation accuracy: +/- 1 mm for each axis

- 2 synchronous long travel axes

- 2 synchronous cross travel axes

- 2 synchronous hoist axes

- extremely low-rise design

semiconductor industry

semiconductor industry

Cleanroom double girder overhead crane

Cleanroom double girder overhead crane

Purpose

extremely sensible handling of high-precision machine assemblies in synchronised joint operation

Functions

- Lifting capacity: 2 x 15 tons each crane

- Span: 30,000 mm

- Lifting height: 8,000 mm

- Cleanroom class: ISO 6

- Synchronisation accuracy: +/- 1 mm for each axis

- 2 synchronous long travel axes

- 4 synchronous cross travel axes

- 4 synchronous hoist axes

semiconductor industry

semiconductor industry

Cleanroom jib crane

Cleanroom jib crane

Purpose

Charging of a cleaning facility with high-precision machine parts

Functions

- Lifting capacity: 1,250 kg

- Outreach: 4,700 mm

- Lifting height: 4,660 mm

- Cleanroom class: ISO 6

semiconductor industry

semiconductor industry

Cleanroom crane – double girder overhead crane

Cleanroom crane – double girder overhead crane

Purpose

extremely delicate handling of sensitive machine assemblies

Functions

- Lifting capacity: 6 to

- Span: 8,660 mm

- Lifting height: 5,710 mm

- Cleanroom class: ISO 6

- extremely low-rise design

research

research

Shared clean room crane – bridge crane with assembly joint

Shared clean room crane – bridge crane with assembly joint

Purpose

extremely sensitive mounting

Functions

- Lifting capacity: 2 tons

- Span: 22,000 mm

- Lifting height: 7,280 mm

- Clean room class: ISO 8/6

- Synchronisation accuracy: +/- 1 mm for each axis

semiconductor industry

semiconductor industry

Cleanroom jib crane

Cleanroom jib crane

Purpose

extremely sensitive mounting

Functions

- Lifting capacity: 2 x 2 tons

- Outreach: 4,900 mm

- Lifting height: 5,500 mm

- Cleanroom class: ISO 6

- with collision control

semiconductor industry

semiconductor industry

Cleanroom double girder overhead crane – tandem operated

Cleanroom double girder overhead crane – tandem operated

Purpose

synchronised lifting of heavy equipment

Functions

- Lifting capacity: 2 x 5 tons

- Span: 9,200 mm

- Lifting height: 3,500 mm

- Cleanroom class: ISO 6

- with tandem control

pharmaceutical industry

pharmaceutical industry

Cleanroom single girder overhead crane

Cleanroom single girder overhead crane

Purpose

Transport of pharmaceutical substances

Functions

- Lifting capacity: 1 to

- Span: 5,500 mm

- Lifting height: 3,300 mm

- Cleanroom class: ISO 7

- with semi-automatic positioning

pharmaceutical industry

pharmaceutical industry

Cleanroom crane – completely ground

Cleanroom crane – completely ground

Purpose

Production area in the pharmaceutical industry

Functions

- Lifting capacity: 1 to

- Span: 3,100 mm

- Lifting height: 3,860 mm

- Cleanroom class:

- ISO 6 according to DIN EN ISO 14644-1 corresponds to Fed. Hrs. 209 D class 1,000 or Fed. Std. 209 E M4.5

- Stainless steel surface: 1.2 μ (completely ground)